Why you should invest in industrial automation

Australia is filled with all sorts of industrial establishments. While some run manually, some have made choices to rely on automation, and that’s the better choice. There are several benefits of industrial operation that serve different kinds of industries including food, paper, power, etc. But most of the time, the reason why entrepreneurs hesitate to switch to automation is the lack of awareness of the subject. Thus, here is the top reason to invest in industrial automation.

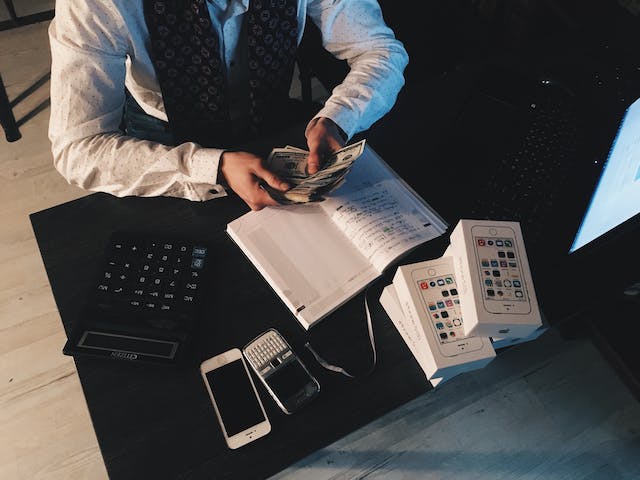

Reduces employee expenditure

There was a time in history when massive production brands had to rely on the competence of their employees for quality assurance. But the requirement of a higher number of employees is the biggest downside of this method. As the number of departments increases within the organization, the multiplication factor of the average paycheck increase. Amidst all that, your business cannot hold back its operations until the complications of the pandemic subside permanently.

Although it is absolutely necessary for some operations to have manual monitoring, automation helps you get rid of all these chunks of unnecessary costs.

Regardless of the nature of the establishment, as long as it involves the controlling and monitoring of analytical variables that relate to a process, you can rely on PLC programming sydney techniques to replace all the unnecessary employees in your business.

Secure quality standards

Although we all make mistakes as human beings, that just cannot be allowed in the commercial sector. The more errors you make, the least would be the quality. One of the best methods to invade the existing market is to showcase the quality standards of your business. Achieving that can be quite difficult with the presence of manually operated processes that can be operated much more concisely with the use of programming. Thus, in taking the quality recognition of your enterprise to higher levels, investing in industrial automation is an absolute necessity.

Improved efficiency

When employees can’t seem to keep up, and the customer demands must be met, the employees will have to keep working under severe fatigue with reduced productivity. This cannot be allowed to continue since efficiency is a key factor in improved industrial operations. Controlling your industrial processes based on computers is the best solution for this. But for that, ideal programming steps should be taken with languages and software that suit your needs. This is why hiring an individual software engineer, or a mechatronic engineer wouldn’t suffice; you need a recognized establishment on board. Once you consult them on the steps to be taken, you will realize the sheer lengths to which you can take your business to and that’s exactly why it shouldn’t be delayed anymore.

Evolving is necessary

You cannot expect to sustain in such a technology-oriented world refusing to adhere to new technology. Not only do these mistakes take away the highest obtainable quality and efficiency, but they also reduce the quality of your production. After all, mere existence as a business isn’t enough. You need to identify the weaknesses of your business and make them your strong suits in the business world following a global pandemic; automated controlling of industrial processes is the best way to do that.

-

Tagged KS